Coaxial Cables with 50 Ohm impedance

Coaxial cable with diameter from 1.8mm to 14.6mm diameter and 50 Ohm characteristic impedance

Coaxial cable by the meter:

Just choose your desired length, we wrap and cut from the manufacturer's drum.

Coaxial cable rings, also called coaxial cable role:

Commercially available cable lengths, wrapped as a ring or role.

Coaxial cable on drum:

Manufacturer bundles wound on wooden drum, plastic drum or role of cardboard.

Aircell 5 Coax Cable 50 Ohm

Art-Nr: 1010790Aircell 7 - 25m-Ring

Art-Nr: 1010800-25mAircell 7 Coax Cable 50 Ohm up to 6 GHz

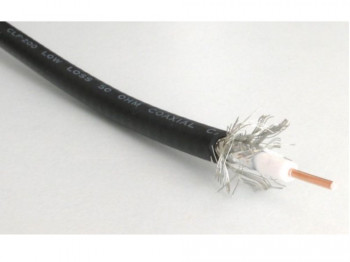

Art-Nr: 1010800CLF 200 Low Loss Coax Cable 50 Ohm

Art-Nr: 1010780CLF 240 FRNC - 50 Ohm Low Loss Coaxial Cable

Art-Nr: 1010732CLF 240 PE - 50 Ohm Low Loss Coaxial Cable

Art-Nr: 1010731Coaxial Cable CLF 240 Low Loss

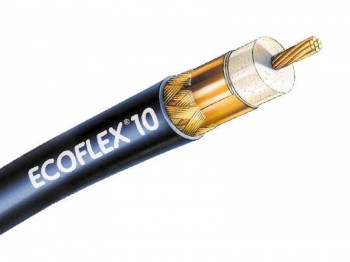

Art-Nr: 1010730Ecoflex 10 Coax Cable 50 Ohm up to 6 GHz

Art-Nr: 1010860Ecoflex 10 Plus 50 Ohm 8 GHz

Art-Nr: 1010864Ecoflex 10 Plus Heatex

Art-Nr: 1010866Ecoflex 15 Coax Cable 50 Ohm

Art-Nr: 1010880Ecoflex 15 Plus Coax Cable 50 Ohm 8 GHz

Art-Nr: 1010884Coaxial cable, coaxial cable, 50 ohms

Energy losses in coaxial lines

There are no lossless cables, but there are low loss cables. The attenuation or loss of a cable depends on many factors. It is obvious and understandable that a thicker conductor has less damping than a thinner one. The conductivity of a pipe also depends on the material. Copper has better conductivity than aluminum or iron. With decreasing temperature, the conductivity increases, so the attenuation becomes lower. The longer a line is, the greater the losses in it. And so there are many more factors in how low-loss a line can be.

A coaxial cable also consists of two conductors, namely the inner conductor, also called the soul and the outer conductor. For several reasons, such as the Einstrahlfestigkeit or vice versa, so the radiation, often multiple line layers are arranged directly above each other to reduce these unwanted radiation to the inner conductor. For coax cable, only the inner conductor is the actual transporter of signals. The outer conductor has two functions, namely to protect the inner line against unwanted radiation and also serves as a second line to close the circuit. Only within a closed circuit can electricity flow.

Coaxial cables are used almost exclusively for the transport of alternating current and only rarely for direct current. And just as the word AC already implies the change, the signal to be transported constantly changes its polarity. It does not matter at all how the signal in the inner conductor changes. The frequency of alternating polarity is of crucial importance and is reported and measured in Hertz. At 50 hertz, like the alternating current from our power grid, the polarity changes 50 times a second. For radio transmissions such as LTE, assuming 800 MHz, the polarity changes 800 million times per second, and for WLAN in the 2.4 GHz range, there are already 2400 million polarity changes per second. And during this frequent change, electrons in the lines are moved back and forth. This electron movement generates friction and friction in turn generates heat. So you also have to make arrangements for the heat dissipation in the cable.

To prevent the inner and outer conductors from touching each other in the coaxial cable and resulting in a short circuit, they must be insulated from one another. And that's not all, because the distance between inner and outer conductor must necessarily remain constant from the beginning to the end of the coaxial line, otherwise the characteristic impedance or the impedance of the cable would change. It would create chaotic, uncontrollable conditions in the cable, if it would come to irregularities or different insulation materials would change within the same line. And the quality of this insulation, which is referred to as a dielectric, also depends on the quality of the coaxial cable. Air as a dielectric has a very high quality, but is not feasible in coaxial lines. Therefore, plastics are used which ensure a constant distance between inner conductor and outer conductor and at the same time have to be a good insulation. The more these plastics can be oxygenated, the lower the losses in the cable. Here are also physical limits, because otherwise the plastic is unstable and the constant distance between the inner and outer conductor can not be guaranteed. Also, the heat dissipation decreases with increasing electron movement. So there are a lot of factors to consider in cable manufacturing to create a reproducible product of consistent quality. Here many compromises have to be made, because the coaxial cable is supposed to be affordable.

Generally speaking, the thicker a coaxial cable is, the smaller its attenuation, and higher its electrical and mechanical strength, with some minor limitations. With increasing diameter, the cable price almost always increases, because more material is processed.